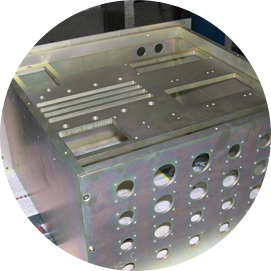

Product model: SG-LD-240H

Dimensions: 440*350*420mm

Product unit: set

Pull head type: flat head round head countersunk head

Pull nail material: Flat head round head countersunk head

Application industry: Stainless steel aluminum iron

TEL:4006-784-785

The fast solid automatic nailing machine is a machine developed by Xunjie Technology to automatically transport and pull the rivet into the nipper nozzle. It has successfully applied for a number of patents and filled the domestic blank. Its use can save your business more than 30% of labor costs.

The fast-fix automatic nail puller is different from the automatic nail puller on the market. The automatic nail puller on the market relies on the hand to pull the rivet into the rivet gun mouth, or the hand-held rivet gun to close the gun mouth to the pull rivet. The rod is sucked into the rivet gun nozzle by the negative pressure in the nipper nozzle; and the quick-fix automatic nail puller is an automatic version of the traditional rivet gun, which relies on the machine to automatically arrange and separate the rivet. With the compressed air as the power, the rivet is automatically conveyed through the pipe to the nipper nozzle. Through the quick-fix automatic nail puller, it is a major technological advancement in the rivet industry to make heavy manual work that relies heavily on skilled workers to upgrade to automated or unmanned work.

| Model | SG-LD-400H | Dimensions | 440x350x420mm |

| Silo capacity | 3000~5000grain | rated power | 350W |

| equipment weight | 45KG | Riveting speed | 1.2~1.5 seconds / grain |

| Pull nail gun | SG-30 | Pull gun weight | 1.2kg |

| working pressure | 6KG | Rated air pressure | 8KG |

| Spike speed | 50~60grain/min | Applicable rivet specifications | 4.0mm |

| Tube length | 2000~3000mm | Back nail length | 2000~3000mm |

| Input voltage | 220V | Low voltage | 24V |

| Automatic feeding | When the rivet is poured into the vibrating plate the feeding can be arranged in an orderly manner to the sub-nail | Have |

| Automatic feeding | When the rivet reaches the nail it can reach the nozzle by the nail tube. | Have |

| Automatic feeding | When the riveting action is completed the next rivet can be automatically delivered to the nozzle | Have |

| Smart counting | LCD monitor can be set to the number setting | Have |

| Missing material alarm | When there is no rivet to reach the nail the alarm light will automatically light up with a voice prompt | Have |

| error alarm | When an abnormality occurs in the machine the alarm light automatically lights up with a voice prompt | Have |

| Number of foolproof | Intelligent counting preventing leakage | Optional |

| Tail collection | The core pulling rod can reach the recycling barrel through the tail nail tube or use the tail nail collecting tube | Optional |

Flying-effect automatic nailing machine is suitable for riveting and drawing of two or more layers of different materials and thickness through rivets.

Widely used in chassis, cabinet, lighting, automobiles, ships, airplanes, small appliances, servers, electric ovens, microwave ovens, liquor packaging and other industries to pull nails.